Add to Cart

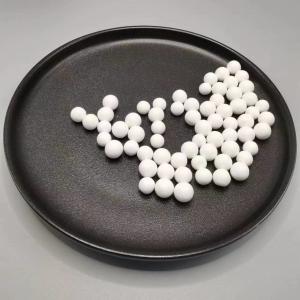

alumina chemical filling ball high purity filling material abrasive medium catalyst covering material

Product name : Alumina ceramic ball

Specification : HY-TCQ-03

Product use :

widely used in petrochemical plants, chemical fiber plants, alkylbenzene plants, aromatics plants, ethylene plants, natural gas and other workshops hydrocracking unit, refining unit, catalytic reforming unit, isomerization unit, demethylation unit and other bottom filling materials. It is used as a support covering material and tower packing for catalysts, molecular sieves, and desiccants in the reactor. Its main role is to increase the gas or liquid distribution point, support and protect the catalyst strength is not high.

Characteristics : high purity, high strength, high temperature resistance, high pressure resistance, strong acid and alkali corrosion resistance, good thermal shock stability, stable chemical properties.

Alumina content :

AL2O3 : 90 %, 92 %, 95 %, 99 %, 99.5 %

Physical indicators :

| condition | index |

| refractoriness under load(yb/t370-1995) | the deformation is less than 0.6 % at 0.2 MPa. |

| heat-shock resistance possessing(yb/t376.2-1995) | 1200 °C to 600 °C, 10 times the surface without cracks |

| reheat linear change(gb/t3997.1-1998) | The maximum value is 0.25 % and the average value is less than 0.20 % when it is kept at 1400 °C for 12 hours. |

| volume density | 3.2-3.50 g/cm³ |

| apparent porosity | 12-18% |

| Maximum operating temperature | 1650℃ |

specification:

3mm,6mm,8mm,10mm,13mm,16mm,19mm,25mm,32mm,38mm,50mm,65mm,70mm.

Workshop display: